5 Lean Ideas Every Engineer Ought to Know

페이지 정보

작성자 Ramonita 작성일24-03-14 06:00 조회11회 댓글0건관련링크

본문

With hundreds of relevant programs to select from, ASME’s accredited, skill-based studying options support the success of your employees and your online business. For a restricted time, get 25% off our on demand programs when you purchase for a gaggle of 5 or more. When you’re able to get began, you possibly can browse our full course catalog here. And if you discover that you've got additional questions about ASME’s learning choices, don’t hesitate to get in contact. Enchancment: Successful organizations have an ongoing focus on enchancment. Proof-based mostly Choice-making: Choices based mostly on the analysis and analysis of data and knowledge are extra seemingly to supply desired results. Relationship Administration: For sustained success, a company manages its relationships with involved events, akin to suppliers. Whereas Complete Quality Management has evolved over time—from primary ideas pioneered by top of the range gurus to the requirements and methods acknowledged by world organizations—its essence of holistically approaching quality management remains.

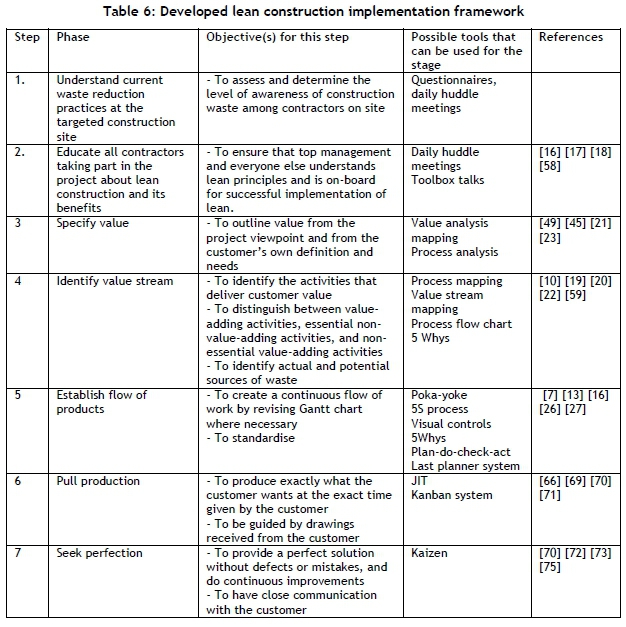

Why Will we Use Worth Stream Mapping? These ideas had been initially put into practice by the extremely regarded Toyota Production System some 70 years ago. Toyota established requirements that when an error occurred throughout an automatic course of, manufacturing can be stopped instantly. And, solely what was wanted could be done at every step in the process. This allowed them to keep up each high quality and speed in making vehicles. What made Toyota’s system so productive and invaluable was that it took into account the circulation of all the course of, quite than just one machine at a time. Every step in the circulation knowledgeable the subsequent, increasing production velocity at decrease costs and maintaining high quality.

Utilizing Trade evaluation gives firms a aggressive advantage and helps them stay related within the industry. Before we begin off with Trade analysis, there are some things which can be to be achieved. First, to perform an Trade evaluation, it is crucial to conduct detailed market research and competitive evaluation so that the outcomes of trade analysis are helpful. Analogously to information producers and customers, four primary varieties of data sources are outlined in industrial analytics environments. Enterprise knowledge sources are all software program methods inside the enterprise OT/IT network that generate and transmit information. This category comprises all kinds of knowledge generated by bodily machines, hardware and other IoT-related units within an industrial setting. Naturally, this category contains the data obtained from the whole number of sensors interpreted into industrial machinery, robotics solutions and numerous different units all of that are built-in into an IIoT community. Your subsequent objective is to secure admission to USC Upstate, and we’re right here to assist you every step of the way. Aim for a GPA above of two.5 to make sure your smooth entry into our vibrant educational community. Stay in the loop and be part of our group by following us on our various social media channels. Our Admissions Instagram account is your window into life on our campus. You’ll get a taste of the vibrant atmosphere and learn about events and important deadlines that matter to you. We’re thrilled to be a part of your journey towards success. Let’s connect, discover, and thrive together at USC Upstate!

Documentation is essential. You might want to know the frequency of components wearing out for preventive maintenance and substitute data should even be collected. The key to profitable total productive maintenance is your crew. These teams are made up from the manufacturing unit ground to upkeep operators and many different departments. Hybrid teams such as these rely on the collaborative-to-the-core ProjectManager, a cloud-based hybrid work management software. Hybrid teams are spread out, some working historically others in a extra agile environment and they need software program that can support their multiple roles. Think of a production line with several workstations and a bulk order. Utilizing one piece circulate, one merchandise is moved into the first workstation, all work there's accomplished, after which the product is moved to the following station. The next product is meanwhile moved to the first workstation. One product is always being labored on at any given stage of the process, and nothing is left ready for a station to be free. Travel occasions between workstations is as restricted as potential (usually by means of an optimized flooring structure) and tasks are grouped to unfold the work as evenly as possible between stations.

By designing products to meet specific wants, companies will remove wasteful steps which will have been required for unwanted features. Design for Six Sigma (DFSS) is one methodology that might help companies establish worth. Utilizing DFSS, firms can systematically outline, measure, and analyze what their prospects need. Companies can then design merchandise tailored for their clients. The second Lean manufacturing Gujarat manufacturing principle is mapping the value stream. A worth stream is the whole life-cycle of a product, which includes the product’s design, the customers’ use of the product and the disposal of the product. This step requires corporations to establish and map the product’s worth stream.

댓글목록

등록된 댓글이 없습니다.